a batteria.jpg)

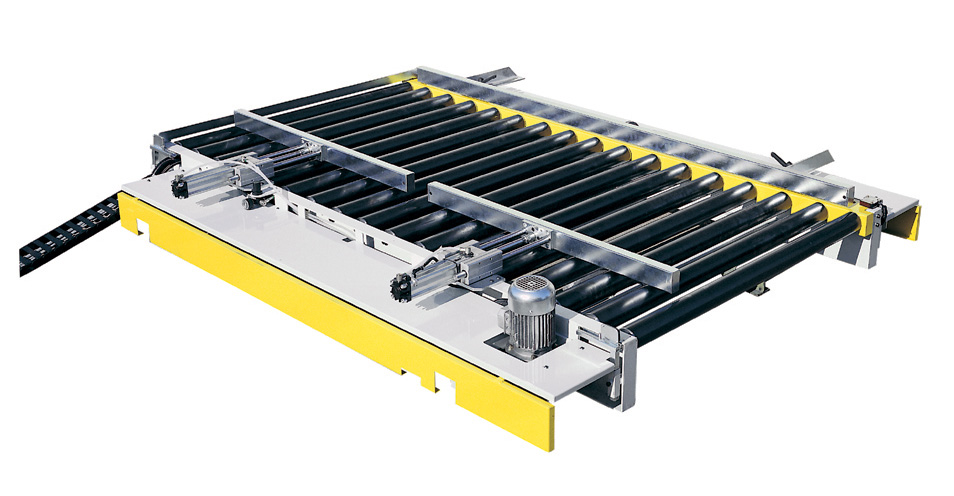

Motorised shuttle

Motorised carts allow to transport materials across departments located far from each other. Motorised transport, in combination with automated loading and unloading of incoming and outgoing carts, allows to cross entire production areas reducing time and improving productivity.

All motorised carts are manufactured in compliance with the applicable regulations and bear the CE marking as required by the machinery directive.

Based on their specific needs, customers can choose three different options.

Shuttle with operator on board

Unlike the battery powered shuttle, it features a standard power cable, normally combined with a cable trolley to avoid tangling.

Suitable for medium distances and semi-automated solutions with an operator managing the loading and unloading on roller conveyors from the shuttle’s platform.

Also suitable for use in more automated systems.

Shuttle without operator on board

Suitable for short distances, doesn’t have an operator on board because normally its work can be controlled from a workstation.

a batteria_1.jpg)

Battery powered shuttle

The total absence of power cables connected to the shuttle is certainly the most convenient feature. Normally, this type of product is combined with the platform for the on-board operator and automation systems to load and unload production lines.

It’s the most suitable product for fully automated systems, with or without operator, and with automated and semi-automated processes.

The battery size is scaled according to the number of work shifts required